Advanced Material Selection & Processing

VID was one of the first companies to use 100% pure vacuum melted 316 LVM stainless steel across our product line. This provides superior mechanical integrity and inert behavior in the physiological environment through homogeneous nano- and micro-structures.

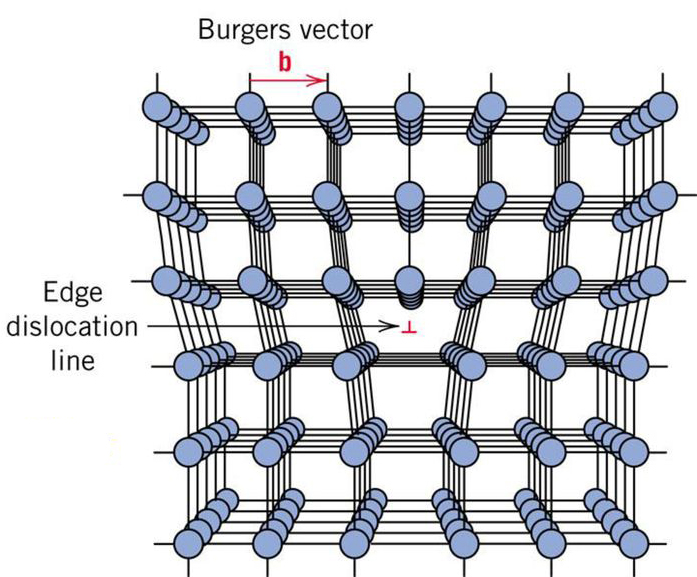

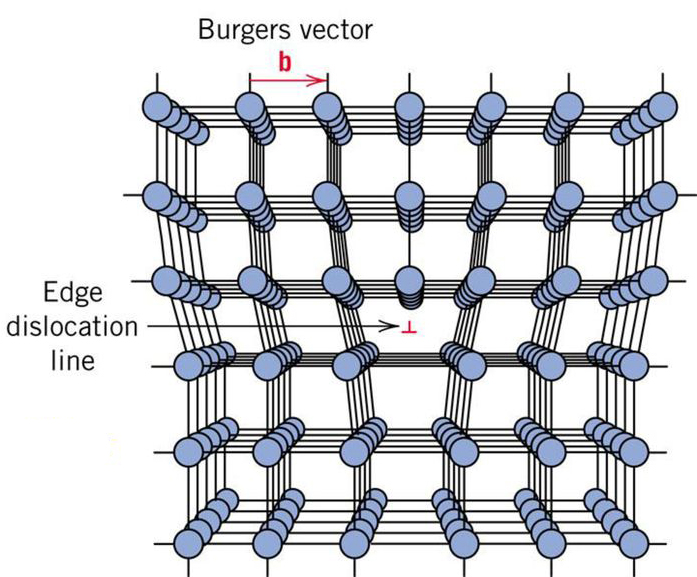

In other words... imperfections within the alloy(like edge dislocations) are minimized in order to create optimal macro-properties.

Additionally, every VID product complies to the highest national and international material quality standards:

- ISO 5832-I: Composition D

- BS 7252/1: Composition D

- ASTM FI 38-97

- DIN 17443 W.-Nr. I.444I

VID was one of the first companies to use 100% pure vacuum melted 316 LVM stainless steel across our product line. This provides superior mechanical integrity and inert behavior in the physiological environment through homogeneous nano- and micro-structures.

In other words... imperfections within the alloy(like edge dislocations) are minimized in order to create optimal macro-properties.

Additionally, every VID product complies to the highest national and international material quality standards:

- ISO 5832-I: Composition D

- BS 7252/1: Composition D

- ASTM FI 38-97

- DIN 17443 W.-Nr. I.444I

Enhancing The Surface

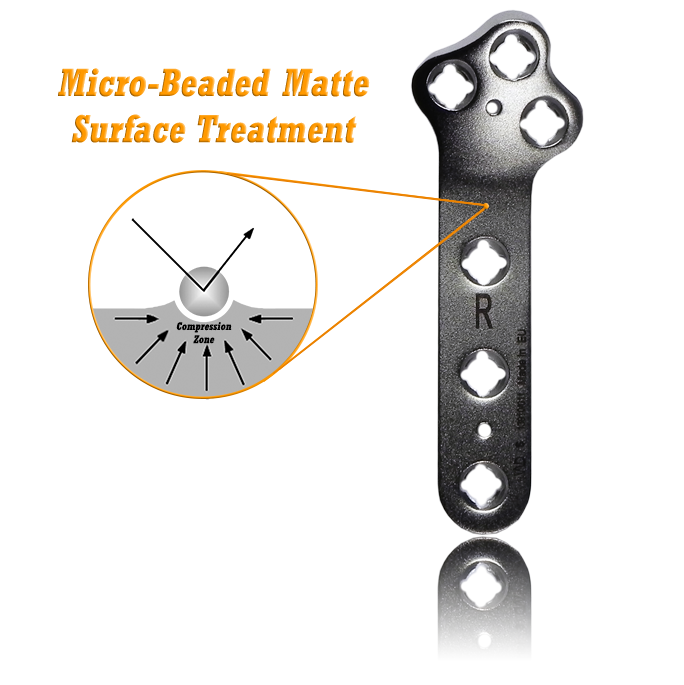

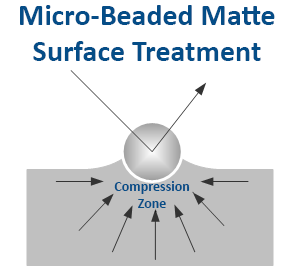

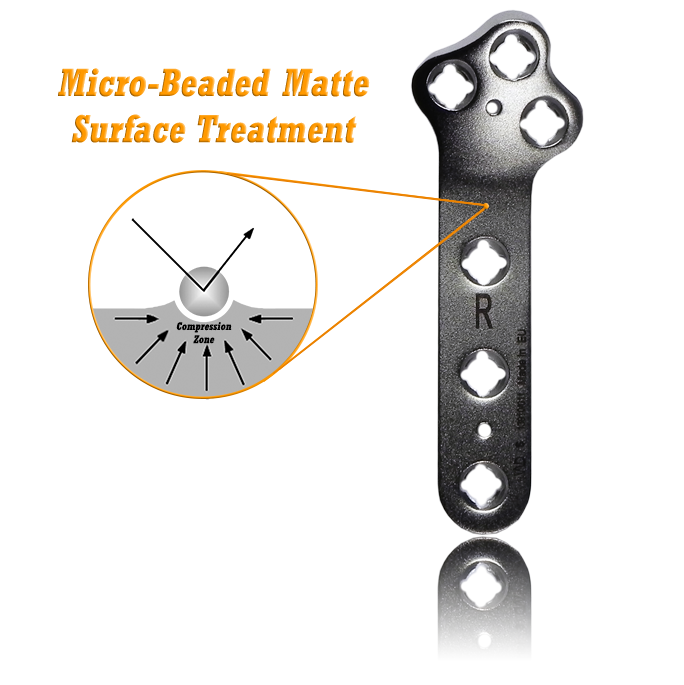

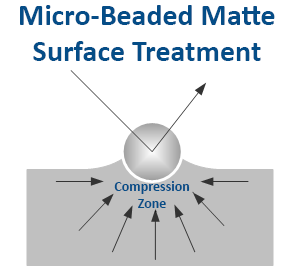

We go a step further by applying an aerospace grade micro-beaded surface treatment that has become the leading alloy surface treatment in the human orthopedic field. During the process, the implant is bombarded with tiny ceramic beads that plastically deform its surface.

It's kind of like a bunch of golf balls being launched at your car.

Enhancing The Surface

We go a step further by applying an aerospace grade micro-beaded surface treatment that has become the leading alloy surface treatment in the human orthopedic field. During the process, the implant is bombarded with tiny ceramic beads that plastically deform its surface.

It's kind of like a bunch of golf balls being launched at your car.

Three Main Benefits are Imparted to the Implant

Enhanced Biocompatibility

Superior Mechanical Properties

Matte Anti-Glare Finish

Research has shown that a matte finish also promotes the recolonization of tissue cells to the alloy before bacteria has a chance to colonize which in turn improves overall bio-compatibility.

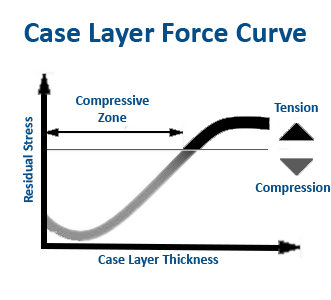

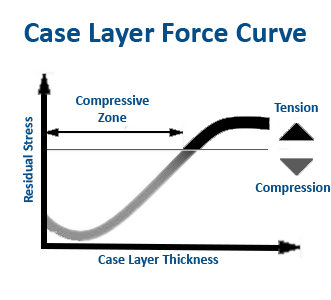

The impact velocity of the beads creates a plastically deformed case layer that applies a residual compressive load, improving cyclic fatigue strength, surface hardness, ultimate tensile strength and overall mechanical integrity.

We all know what it's like to be blinded in the OR! As a practical benefit, a matte surface increases visibility during surgery by reducing glare.

Enhanced Biocompatibility

Research has shown that a matte finish also promotes the recolonization of tissue cells to the alloy before bacteria has a chance to colonize which in turn improves overall bio-compatibility.

Superior Mechanical Properties

The impact velocity of the beads creates a plastically deformed case layer that applies a residual compressive load, improving cyclic fatigue strength, surface hardness, ultimate tensile strength and overall mechanical integrity.

Matte Anti-Glare Finish

We all know what it's like to be blinded in the OR! As a practical benefit, a matte surface increases visibility during surgery by reducing glare.